主动磁性轴承

优化系统效率,提高可靠性和可持续性

好处

我们在径向和侧面组合配置和XcelfLux™磁轴承中提供PowerFlux™磁轴承,具有独特的线圈架构。CALNetix的主动磁轴承的独特优点包括以下内容:

非接触式的支持

CALNETIX的主动磁轴承在设计高速旋转机械时,在传统的滚子或流体膜轴承上具有独特的优势。与传统轴承不同,AMBS将目标转子悬挂在磁场中。结果是非接触式转子支撑系统,具有极低的摩擦和没有接触磨损。非接触式磁轴承的一些好处包括:

- 低功率损耗和发热

- 可实现更高的速度

- 低音噪音

低振动传动性

Calnetix采用自适应同步排斥力算法,以最小化从转子传递到外壳的振动。低传递振动在食品、医疗和国防工业的高精度应用中非常重要。低振动传递率的好处包括:

- 最小化磁性轴承结构振动

- 减小磁轴承的动态载荷

- 减少MBC功耗

- 显著降低可听噪音

运行状况监视和诊断

CALNETIX主动磁性轴承产品设置简单,允许用户监控磁性轴承系统的健康。CALNETIX的AMB包括位置传感器,磁力执行器和微控制器,使机器健康监控和诊断易于访问。通过与外部计算机的连接,识别,分析和归档机器的健康和历史性能都可以通过先进的诊断。可以通过添加CALNetix的高频数据捕获硬件和接口来增强健康监控。

一些健康监测功能包括:

- 通过现场振动轻松监控

- 能够监控所有轴中的轴承载荷

- 能够录制高级数据和故障日志记录

- 可选的数据采集加载项提供更高质量和更高分辨率的数据

集成机器设计的最先进的方法

在大多数情况下,CALNETIX利用广泛的多学科内部专业知识,与客户一起使用,以在磁轴承上设计整台机器,而不是简单地提供磁性轴承部件。这实现了机器作为集成系统的最佳性能,并充分实现了磁轴承系统的潜力。Calnetix的一些竞争优势包括:

- 广泛的内部专业领域,包括机械,电磁,旋转动力,热和电子设计和分析

- 精致的专有设计和优化代码,允许更快地产生优化的磁轴承几何形状,迭代较少

- 来自内部内部和第三方FEA模块的组合的分析解决方案

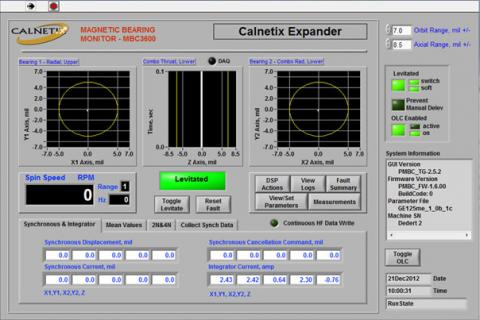

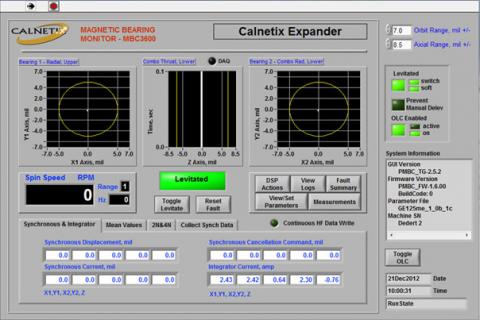

高级图形用户界面

Calnetix开发了一种新颖的图形用户界面(GUI),为用户和专家提供了一种直观的方式来使用磁轴承系统的固有优点。这个GUI已经在内部和外部客户反馈的基础上不断改进和升级。该GUI提供了深入了解磁轴承和机器性能的所有方面。它是系统设置、监控和诊断的平台:

- 自动机械通关检查

- 自动电气连接试验

- 转子升定到任何所需位置,用于操作或测试需求

- 调试具有更简单的内置传输功能和频率响应工具

ray电竞竞技

Powerflux™amb利用同极性永磁偏置磁场与电磁场结合,而Xcellflux™amb利用异极性电磁偏置磁场与电磁控制场结合。这两种产品ray电竞竞技都是低成本和易于组装,如下所示和描述。

PowerFlux™

Xcelflux™

PowerFlux™

- 永磁体(PM)偏见

- 同极的设计

- 径向和轴向轴承的组合

- 高性能低功耗和低冷却要求

- 适用于高性能和精密应用,包括防御,机床,发电和小于1兆瓦和气体压缩机和扩展器

成分

磁性轴承不起眼;它们需要多个组件作为一个独特的系统。CALNETIX已经设计和开发了构成主动磁性轴承系统的所有组件,下面显示和描述这些组件。

执行器

位置传感器

速度传感器

备用轴承

磁性轴承控制器

图形用户界面

执行器

主动磁轴承中的致动器是电磁铁,它向机器的轴施加控制力以控制其位置。径向作动器由层叠控制线圈和极点组成,以提供两个正交的控制轴。在Calnetix执行器中还使用了一组永磁体来产生线性偏置磁通。其他的AMB制造商在控制线圈中产生直流电流的线性化磁通。另外两种常见的致动器配置是组合径向/轴向致动器和独立轴向致动器。

AMB执行器必须连接到磁性轴承控制器(MBC),该控制器基于位置传感器反馈信号和控制算法将控制电流提供给线圈。

想了解同极、永磁偏置主动磁轴承的工作原理,请点击在这里。

位置传感器

位置传感器是任何主动磁轴承的关键部件。它们的作用是为了连续地提供关于转子位置的准确最新信息,这些转子位置不受外部因素,例如速度,温度,灰尘,工作流体,外部磁场和电场等。即使大大进展在开发自感应的AMB方面是制造的,其中位置测量和力产生的功能在一个物理成分中组合,它们的基本性能限制可能会限制在低成本,低速机器上的用途。利用专用径向和轴向传感器的传统轴承装置将保持占主导地位。

不同类型的位置传感器具有不同的性质组合,使它们中的一些更适合于给定的应用而不是其他的应用。然而,在工业环境中,通常优选具有一种可以涵盖尽可能多的应用的技术。从各种可用技术,包括光学,电容和电磁位置传感器,后者似乎是最通用的解决方案。CALNETIX使用四种类型的传感器,具体取决于应用程序细节:

所有传感器包括位于机器中需要测量位移的敏感元件(传感器头)和传感器电子元件,通常位于磁轴承控制器(MBC)中。

速度传感器

速度传感器提供有关旋转速度的信息和转子所需的旋转速度和角度位置的信息,以及调节控制参数的信息,并使转子不平衡消除。CALNETIX使用两种类型的专用速度传感器。两个传感器都利用了直流磁场的源极,霍尔效应元件测量该场和转子上的特征,例如凹口调制磁场。

- 智能速度传感器-智能速度传感器利用一个内置磁铁作为磁场源,两个霍尔效应传感器用于微分场测量和一个内部逻辑,寻找磁场随时间变化的周期模式,然后将其解释为速度。由于这些传感器的设计是为了寻找磁场的任何周期模式,无论水平,他们不需要任何校准,非常容易使用。缺点是,它们在灵敏度调整方面没有任何灵活性,而这在某些应用中可能是需要的。

- 可编程速度传感器- 这些传感器利用两个可编程霍尔效应传感器和磁场的外部源。可以调整可编程霍尔效应传感器的参数以解决特定应用程序的细节。这些传感器通常集成到径向致动器的“死杆”中,以利用已有的致动器偏置磁场。这显着降低了机器的轴向长度,并允许更大的旋转动力边距。

备用轴承

当磁性轴承系统停用时,备用轴承提供对旋转组件的支撑,并在过载的情况下提供转子支撑磁性轴承或者磁力轴承的某些部件发生故障。在正常运行中,后备轴承是不活跃的,因为他们将有一个小的径向和轴向间隙的旋转组件。这个间隙最多是磁轴承气隙的一半,通常相当小。

CALNETIX使用的最常见的备用轴承配置是两个双工对角接触球轴承,预加载面对面(DF)。该安装需要夹紧外部比赛 - 牢固地或通过弹簧 - 在外圈上。具有传统SAE 52100钢种族和SIN3球的混合轴承是标准的。用于高速应用的备用轴承通常是不同声的,并且使用油脂膜,干膜润滑剂或轻润滑脂填充。

磁性轴承控制器

雷电竞下载appCALNETIX Technologies已开发和部署先进的磁轴承控制器(MBC),其包含操作磁性轴承系统所需的所有元件。该公司目前在Insight™系列中生产了两个不同的MBC平台,并在Concurrence™系列中。

有关更多信息,请参阅磁轴承控制器产品页面。

图形用户界面

CALNETIX服务图形用户界面(GUI)用于系统设置,监控,诊断和系统识别。前面板的上半部分如下所示,从两个径向轴承传感器和轴向轴承传感器的时间历史图显示轨道图。所示的其他操作变量包括旋转速度,静态电流和同步位移和电流。还显示出状态变量,例如悬浮和故障状态。右侧的系统信息窗口为GUI,固件,参数文件和机器序列号说明符提供了版本信息。

可以通过操作按钮访问更详细的信息或功能:数字信号处理器(DSP)操作,查看日志,故障摘要,查看/设置参数和测量。附加功能包括:

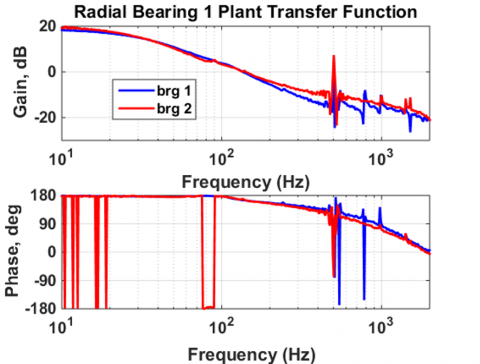

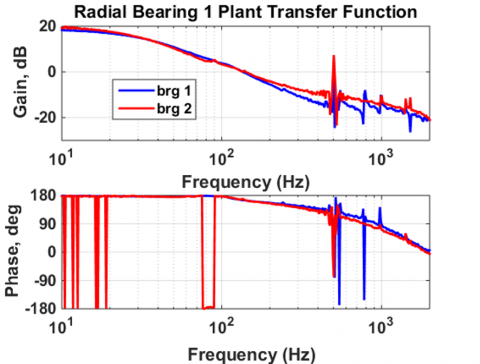

- 传递函数测量-设备传递函数,补偿器传递函数,开环传递函数,闭环传递函数和灵敏度传递函数

- 日志-故障,事件,ESD数据,机器特定的校准和系统数据

- 范围。关键操作信号的内部高频测量,如转子运动和线圈电流(致动器力)

- 连续数据采集-长期记录高频数据,如磁盘存储的位置、电流和速度

为什么使用主动磁轴承?

主动磁性轴承(AMB)已在商业旋转机械中超过30年,由于无摩擦操作和缺乏可穿戴部件,提供了增加的性能和扩展机寿命。磁性轴承系统的生产行业幅度幅度,导致总成本降低和更快的市场采用。切换到磁轴承的一些优点包括:

- 旋转部件与静止部件之间没有物理接触

- 无需润滑系统(环保)

- 在恶劣环境中功能齐全

- 低功率损失

- 动态测试,健康监控和数据记录

- 还有很多…

查看有关AMB优势的更多信息,点击这里。